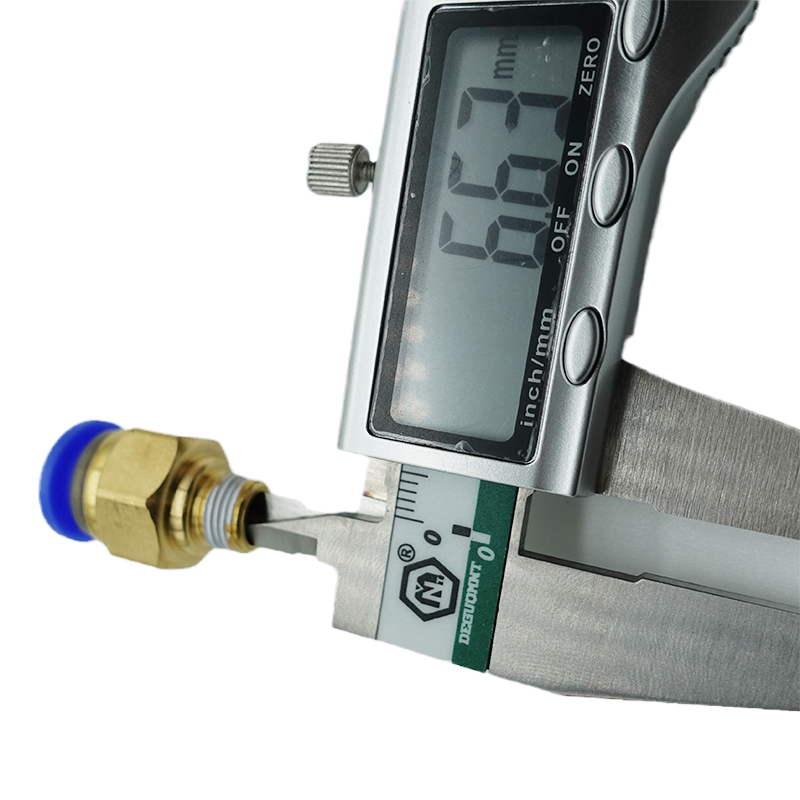

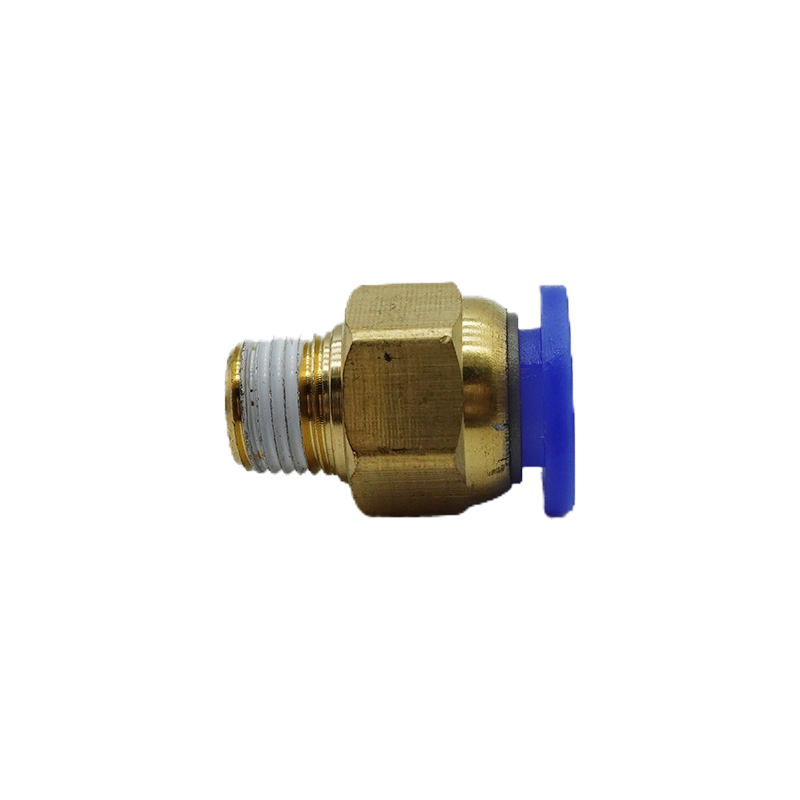

Pneumatic fitting push in quick connector fittings PL10-01

- Model:

- PL10-01

- Place of Origin:

- China

- Application:

- Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Home Use, Retail, Printing Shops, Construction works , Energy & Mining

Description

Pneumatic joints are generally produced using PU raw materials, with stable quality, high pressure resistance, weather resistance, wear resistance, bending resistance, smooth and flexible pipe body, bright color, high elasticity, resistance to bending, and small bending radius

Key Features

There are three types of pneumatic connectors:

1. Two end open close type:

When linking - When the descendant is inserted into the parent body, the collar returns to its original position under the action of the spring, the steel ball rolls and locks the descendant body tightly, and the valve between the parent body and the font pushes each other to open, allowing fluid to flow. The O-ring can completely block fluid leakage.

2. Open end

When not linked: When the ferrule of the parent body is pushed to the other end, the steel ball automatically rolls outward, thus the child body is removed; Due to the lack of valves in both the font and matrix, fluid flows outward.

Link: When the descendant is inserted into the mother body, the ferrule is pushed to the previous position by the force of its spring, causing the steel ball to lock and the fluid to flow. The O-ring inside prevents liquid leakage

3. Single circuit open close type

When not connected: When the ferrule of the parent body is moved to the other end, the stainless steel ball automatically rolls outward, and the child body is opened by the reaction force of the valve spring. The valve can automatically close to block fluid flow.

When connecting: When the descendant is inserted into one side of the mother body with a collar, the valve is opened, causing fluid to flow. The washer is pushed back to its original position by the force of the spring, and the stainless steel ball is locked to ensure the connection between the descendant and mother body. The washer inside can completely block fluid leakage

Applications

Pneumatic Systems: The Solenoid Valve is extensively used in pneumatic control systems to regulate air flow for equipment operation and automation.

Hydraulic Systems: It plays a crucial role in hydraulic circuits, controlling the flow of hydraulic fluid for precision movement and system safety.

Process Control: In industries such as chemical processing, Solenoid Valves are employed to monitor and regulate the flow of liquid and gas in various production processes.

HVAC Systems: Solenoid Valves are often utilized in heating, ventilation, and air conditioning systems to control the flow of refrigerant gases and ensure efficient cooling or heating.

Water Treatment: They are widely used in water treatment plants for automatic control of water flow, preventing overflow, and maintaining optimal water levels.

In conclusion, the Solenoid Valve proves to be an essential component in various industrial applications. Its reliable performance, fast response time, and versatility make it an ideal choice for controlling fluid and gas flow. With its wide range of applications and ease of installation, the Solenoid Valve is a reliable and efficient solution for numerous industries.

Specifications

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Home Use, Retail, Printing Shops, Construction works , Energy & Mining